AIRTECT Plastic Leak Detection: Preventing Downtime, Reducing Waste, and Enhancing Production Efficiency

The Costly Reality of Plastic Leaks in Manufacturing

Did you know that undetected plastic leaks in injection molding machines contribute to millions of dollars in losses each year? From wasted materials and machine downtime to expensive repairs and safety hazards, plastic leaks pose a significant threat to manufacturing efficiency. Despite advances in technology, many manufacturers still rely on reactive maintenance strategies, leading to costly disruptions. This is where AIRTECT Plastic Leak Detection comes in. As an advanced plastic leak detection system, AIRTECT helps plastic manufacturers detect leaks in real-time, preventing downtime, reducing waste, and improving production efficiency. Let’s explore why plastic leak prevention is crucial and how AIRTECT’s innovative solution can transform your manufacturing process.

The Challenge: The Hidden Dangers of Plastic Leaks in Manufacturing

Why Are Plastic Leaks a Major Issue?

Injection molding is a highly complex process that requires precise control of temperature, pressure, and material flow. However, a undetected leak can quickly result in:

- Production downtime – Plastic leaks cause costly molding machine shutdowns.

- Product defects –If the leak is not detected quickly, inconsistent material flow will impact product quality.

- Equipment damage – Leaks damage sensors, heating elements, and other critical components.

- Safety hazards – Molten plastic leaks poses risks and fire hazards to workers and equipment.

Real-World Impact: The Cost of Undetected Plastic Leaks

Consider this scenario: A large-scale automotive parts manufacturer experiences a production halt due to a plastic leak in a large mold. Engineers and maintenance personnel must spend many hours or days cleaning the mold and replacing all of the damaged heaters and thermocouples. This leads to many thousands of dollars in lost productivity and the purchase of replacement parts. With just in time production requirements these costs can spiral out of control if the mold is not put back into production quickly. After implementing AIRTECT’s plastic leak detection system, they can quickly identify plastic leaks and repair and clean the mold in just a few hours resulting in a large reduction in downtime and significant cost savings.

How AIRTECT Plastic Leak Detection Solves the Problem

Real-Time Monitoring for Proactive Leak Prevention

Unlike traditional leak detection methods such as manual inspections or infrared monitoring, AIRTECT offers a fully automated, real-time detection system that provides instant alerts on potential leaks.

Key Benefits of AIRTECT’s System:

- Early Leak Detection – Identifies plastic leaks before they escalate into major problems.

- Reduced Downtime – Prevents unexpected machine failures and costly shutdowns.

- Improved Safety – Protects workers from hazards caused by undetected plastic leaks.

- Seamless Integration – Easily interfaces with existing injection molding machinery.

How It Works

AIRTECT’s plastic leak detection system consists of highly sensitive sensors that monitor airflow at locations in the mold or at the machine injection nozzle. If a leak occurs, the system detects the deviation in airflow and triggers an immediate alarm, allowing operators to take quick corrective action. This proactive approach ensures that manufacturers maintain high production efficiency without the risk of unexpected failures.

Comparison: AIRTECT vs. Traditional Plastic Leak Detection Methods

| Feature | Manual Inspection | Infrared Monitoring | AIRTECT Plastic Leak Detection |

|---|---|---|---|

| Real-Time Alerts | No | No | Yes |

| Automated Monitoring | No | Partial | Yes |

| Prevents Downtime | No | No | Yes |

| Integration with Machines | No | Limited | Seamless |

| Cost Savings | High Losses | Moderate Losses | Maximum Savings |

Best Practices for Plastic Leak Detection in Plastic Manufacturing

While AIRTECT provides an advanced solution for plastic leak detection, manufacturers can further enhance production efficiency by implementing these best practices:

- Regular Maintenance Checks – Schedule frequent inspections to ensure all equipment is in optimal condition.

- Utilize Real-Time Monitoring – Invest in an automated plastic leak detection system like AIRTECT.

- Train Staff on Plastic Leak Prevention – Educate employees on the use and set up of the AIRTECT system and the importance of its use.

- Perform Root Cause Analysis – If plastic leaks occur, identify the underlying cause and implement preventive measures.

By combining these strategies with AIRTECT’s cutting-edge technology, manufacturers can eliminate unplanned downtime and enhance productivity.

FAQs About AIRTECT Plastic Leak Detection

-

How does the system detect leaks in real-time?

AIRTECT uses sensitive airflow sensors to monitor small tubes mounted in the mold or machine injection nozzle. When a leak occurs, the system detects variations in airflow and triggers an alarm, allowing immediate corrective action.

-

What types of plastic manufacturing processes can use AIRTECT?

AIRTECT is ideal for injection molding, extrusion, blow molding, and other plastic production methods that have areas where plastic leaks can occur.

-

How much downtime can AIRTECT help prevent?

By detecting plastic leaks early, AIRTECT can significantly reduce downtime leading to large operational cost savings.

-

Is the system easy to integrate into existing production lines?

Yes! AIRTECT is designed to be plug-and-play, allowing seamless integration with existing plastic injection molds and machinery.

Protect Your Production. Reduce Waste. Maximize Efficiency.

Plastic leaks have a significant impact on manufacturing operations. From costly downtime, mold and machine damage and safety risks, the consequences can be devastating. With AIRTECT Plastic Leak Detection, manufacturers can proactively prevent plastic leaks, ensuring smooth production, cost savings, and enhanced product quality.

Don’t wait for the next costly plastic leak to disrupt your operations. Contact us today and see how AIRTECT can protect your plastic manufacturing business!

AIRTECT LA500 ‘SINGLE’ Injection Nozzle Plastic Leak Detection Solutions: Complete Kit

$725.00

-

AIRTECT LM2050 Injection Nozzle Plastic Leak Detection Alarm & Control Unit

$965.00

Add to cart

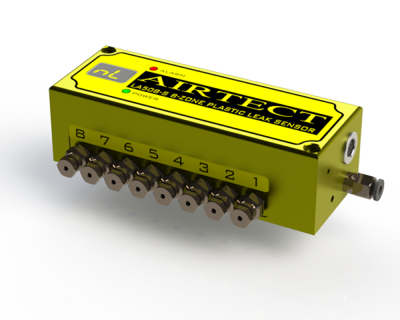

AIRTECT LA508S 8-Zone Fixed Stand-Alone Leak Alarm Manifold

$2,370.00

Select options

This product has multiple variants. The options may be chosen on the product page