For injection molders, flowmeters offer cost-effective, automated monitoring of water flow to prevent product defects, mold damage and downtime.

Consistent flow of water is critical for ensuring the right temperature and pressure needed for injection molding parts with precision and maximizing production throughput.

When the flow of water is inconsistent, it can adversely affect dimensions of the part, leading to costly part defects.

For medical injection molding, even a microscopic part defect on a heart valve or other medical implant can pose a serious risk to patient safety. If water flow drops, due to a hose being crimped, mold cooling channel rust, or something else affecting water flow, the temperature in the mold can change. This can affect dimensions of the part, leading to defects that are not visually apparent – down to a few thousandths of an inch.

If the flow of water drops far enough, or a mold is turned on without water being supplied at all, costly mold damage and downtime are likely in addition to part defects.

Flowmeters help you prevent all of these problems.

How Electronic Flowmeters Work

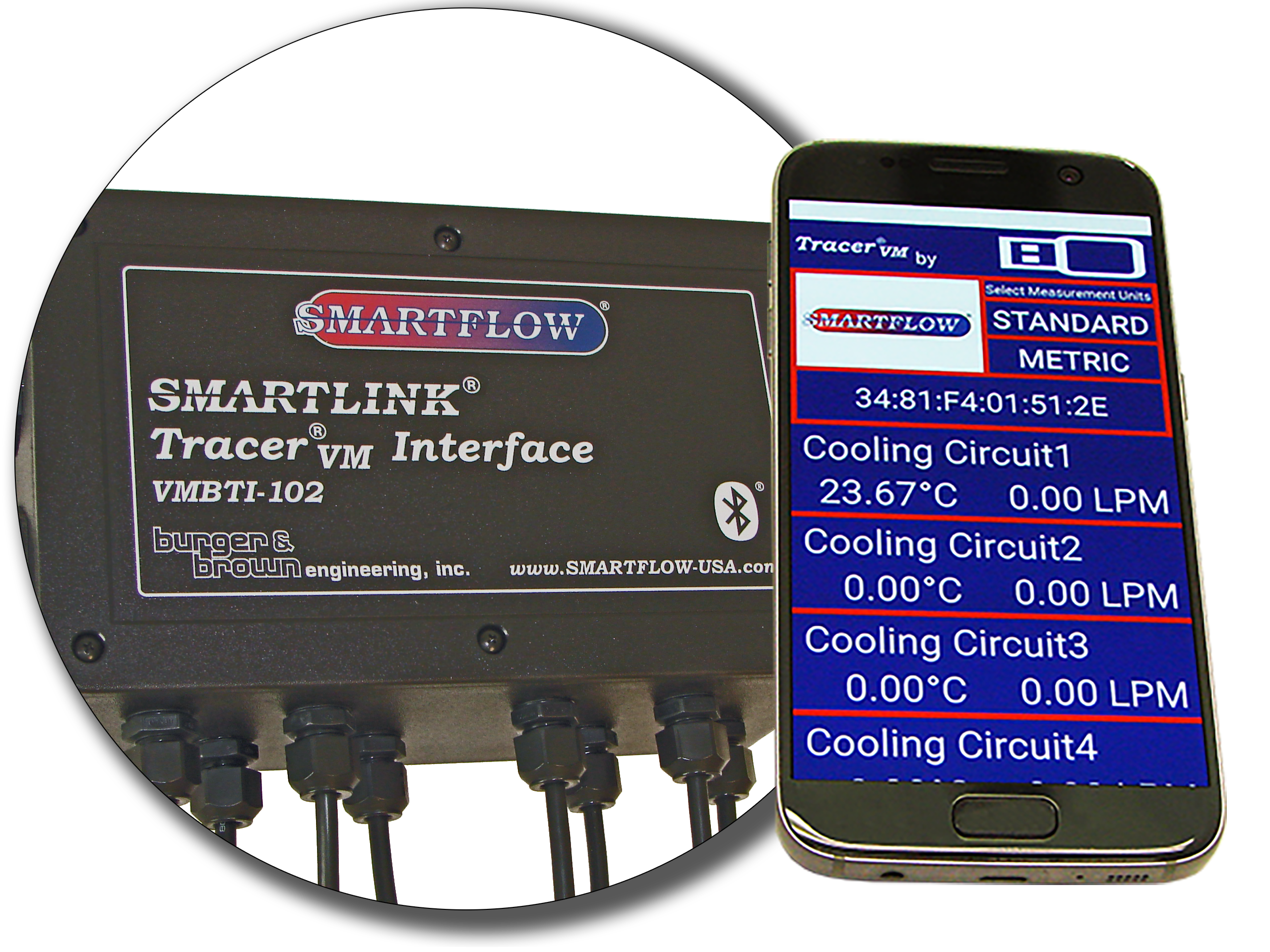

The SMARTLINK™ Tracer®VM Interface collects data from TracerVM flowmeters installed within an injection mold cooling circuit. If flow drops, there is a switch that will change state, and it can be connected to a stack light or an audible alarm. There is also a visual display on the datalogger software that will alert the user when the programmed values are exceeded. This will be either low or high flow, or low or high temperature. The alert is dependent upon the user-set target, and these set points can also be disabled by the user as needed.

Aggregating up to eight separate flowmeters, the SMARTLINK TracerVM Interface provides power to each flowmeter and receives voltage signals for temperature and flow. Additionally, the interface offers:

- A mobile app to monitor temperature and flow conditions in real time

- Simplified multiple TracerVM installations

- Gasketed, water-resistant plastic enclosures

- Ethernet port to connect to local network

- USB port provides mobile device charging plus flash drive connection

- SMARTFLOW® Data Logger PC software included

Avoiding Production Downtime

Flowmeters can also ensure injection molding machines are “ok to run” to prevent costly damage to the mold if an operator starts the machine without the water supply turned on.

To do so, flowmeters are placed on the return inlet for the mold temperature controllers and tied into a data card on the machine, other type of alarm or hot runner control system that will visually indicate when the correct water temperature and flow are in place to start operation.

This is especially important for medical injection molders: a $0.50 defective part could threaten the integrity of costly medical devices. A large, world-class medical injection molder started using flowmeters two years ago. In the first month, the flowmeters prevented three events that would’ve cost $30,000 to $50,000 in defective parts reaching their medical device assembly lines.

We learned of another situation where flowmeters weren’t being used and an injection molding machine producing plastic bottle tops was turned on without water flow to the mold. As a result, a mold plate cracked that took five weeks to replace on a critical production mold that could not afford any downtime.

Identifying the Right Flowmeters

Monitoring the temperature and consistency of water flow is critical to part integrity, quality control, protecting molds, and meeting production goals, which is increasingly difficult to do with the lack of skilled labor and increasing automation that otherwise wouldn’t catch these problems.

Previously, flowmeters were only used by the largest injection molders that discovered how valuable and inexpensive they are. Machine manufacturers are increasingly incorporating flowmeters on new machines, but many injection molders would benefit from using them on molds now in production.

Additionally, other equipment can be tied into flowmeters easily, including hot runner temperature controllers and RJG process monitoring control systems. If you already have an RJG system, a flowmeter board might only cost about $500.

Not sure where to start? The Plastixs team can help you determine the right technology for your needs. We have decades of experience helping clients find cost-effective solutions to ensure part quality, maximize uptime and prevent costly problems.