Hoses take a beating in the plastics industry.

Many standard PVC hoses do not stand up to the daily wear and tear of plastics manufacturing applications for long.

Exposure to heat and abrasion can soon overcome the structural integrity of PVC hoses and the real cost of replacing them is measured in downtime.

That is why many plastics processors, especially those working with resins that require high-heat drying, go looking for hoses with more staying power and resilience.

It’s a search that quickly leads to Plastixs’ NORRES product line.

Minimize Downtime & Replacement Costs

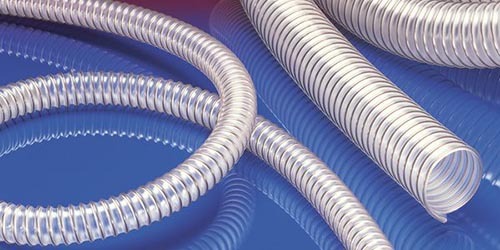

Long-lasting and cost-effective, NORRES hoses are made of polyurethane and outperform

traditional PVC hoses for heat-resistance, flexibility and lifespan – critical metrics that can go straight to your bottom line.

Here’s a quick breakdown of the advantages:

- Increased Temperature Range: the maximum temperature for a PVC hose is 150°F; the standard NORRES hose is rated for up to 195°F and the high temp version can stand temperatures of up to 255°F of continuous operation

- Flexibility: NORRES hoses are more flexible at different pressure ranges and for operations that require movement in multiple directions or flexibility against vacuum forces

- Grounding: NORRES hoses are made from static dissipative material and do not require grounding

- Wear Resistance &Minimal Downtime: greater overall wear resistance means less downtime spent replacing hoses

Work with the High Temperature Experts

At Plastixs, we offer a variety of NORRES polyurethane hoses (also called PU hoses) to solve your plastics processing challenges, including:

- NORRES highly abrasion resistant suction and transport hoses

- NORRES hot air and high temperature hoses

- NORRES hose clamps

Plastixs ensures plastics processors perform at their full potential by supplying and manufacturing unique components, accessories and supplies—especially high temperature hoses and water manifolds—that tie these systems together, increase productivity and prevent small issues from creating big problems.

Talk to our high temperature product experts to identify and deliver the right high temperature solution for you to minimize replacement costs, downtime and injuries.