Established in 1889, NORRES has become a global leader in the manufacturing of polyurethane material handling hoses and is increasingly used in the plastics industry due to several appealing performance characteristics that make it well-suited for injection molding, extrusion and blow molding applications.

Below are the top five reasons that NORRES hoses are ideal for use in the plastics industry.

1. Temperature Range

Plastics processing can involve high-temperature resin conveyed in operations like extrusion and injection molding. NORRES hoses are manufactured with special polyurethane materials designed to withstand the higher temperatures involved in conveying engineered resins from material dryers.

Standard NORRES hoses are rated for 195°F (90°C) continuous and 255°F (123°C) intermittent material temperatures and NORRES High Temperature (HT) hoses can endure material temperatures at 255°F (123°C) continuous and 300°F (148°C) intermittent.

2. Abrasion Resistance & Long Life

In the plastics industry, abrasive materials like glass or mineral-filled plastic pellets, and recycled material of all types, are frequently transferred through hoses in material handling systems where they cause wear and ultimately downtime.

NORRES hoses are known for their excellent abrasion resistance, ensuring a longer service life and reducing the need for frequent replacements. The unique hose construction and polyurethane material are extremely durable and can extend the hose lifespan 5 to 10 times longer than many PVC hoses.

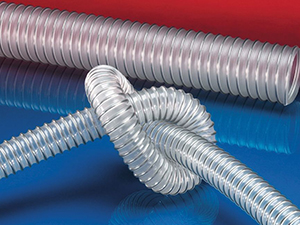

3. Flexibility & Bend Radius

The plastics industry often requires hoses that can be easily maneuvered and routed through complex material systems and tight, compact spaces. NORRES hoses are engineered to provide superior flexibility for each hose type versus similar hoses on the market. The small bend radius of these hoses makes for easy installation and handling when equipment is serviced.

4. Static Dissipation

Static electricity can be a significant concern in the plastics industry, as it can cause issues like material sticking to the walls of the hose during material transport or even create sparks that could lead to explosions in certain conditions. NORRES polyurethane hoses are constructed with antistatic properties compounded into the hose wall so you gain all the benefits of static free operation without the need of a grounding wire.

5. Food-Grade Options

For applications where plastic materials are used in food processing, medical molding, and packaging, NORRES offers food-grade hoses that comply with all relevant safety standards.

Get Started Today

Overall, NORRES hoses provide the plastics industry with reliable, durable, and effective solutions for material handling, contributing to streamlined operations and improved product quality. The Plastixs Team has over 8 years of experience with NORRES hose and is ready to help you identify the right products for your application.

Contact us to learn more about NORRES hoses for injection molding