USA’s Top Custom Manifold & Manifold Assembly Experts

Talk to Our Manifold Experts Now.

Custom, Assembly & Manifold Parts & Components are Our Core Business

Over 20 Years building custom manifolds

Hundreds of Custom Assemblies Delivered Annually

100% Leak-Tested Before Delivery

Built in the USA

Trusted by Leading Industrial OEMs and Plastic Processors Nationwide

Shop Manifold Components

Maximize Machine Output: How the Right Manifold Design Drives Better Results

Here’s How Our Custom Manifold & Manifold Assembly Process Works:

Consult

Tell us about your application, pressure, flow and system requirements, and performance goals.

Design

We’ll create a custom manifold solution tailored to your exact specifications.

Parts, Fabrication & Assembly

We’ll select and source parts and materials and fabricate what is required.

Test & Deliver

Receive a fully assembled, leak-tested, production-ready manifold that installs easily and works flawlessly.

From Lasers to Large Variable Speed Drives, Our Manifolds Cool Them All

- Injection molding

- Blow molding

- Lasers

- Vacuum pumps

- X-ray applications

- Semiconductor tools

- Large variable speed drives

- Power supplies of all sizes

- Server cooling

- Specialized welding equipment

- MRI equipment

- HVAC distribution manifolds

And Many More…

Easy to Integrate and Simple to Install

- Fully configurable to your application

- Unique “Plug-n-Play” concept provides quick & easy installation

- Special “Kits” available for High Temperature applications

Designed to Fit. Built to Last.

Trusted Experts in Custom Manifold Solutions & Assembly

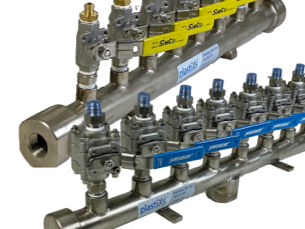

At Plastixs, we’re known in the industry as The Cool Guys—and for good reason. With over two decades of experience, we specialize in designing, engineering, and assembling custom manifolds that solve real-world production challenges across plastics processing and industrial OEMs.

Your Go-To Source for Custom Manifolds, Components & Assembly

From simple circuits to complex multi-zone systems, we build custom manifold assemblies tailored to your exact molding system and production requirements. Every manifold is leak-tested, precision-built, and made to work flawlessly right out of the box.

Built for Efficiency. Backed by Experts.

Plastixs custom manifold assemblies improve flow control, reduce downtime, simplify installation, and optimize performance for everything from water lines to thermolators to complex hot runner systems.

Engineering Support That Goes Beyond the Blueprint

Our team is here to provide full design, application, and troubleshooting support—for your plant staff, OEMs, and system integrators.