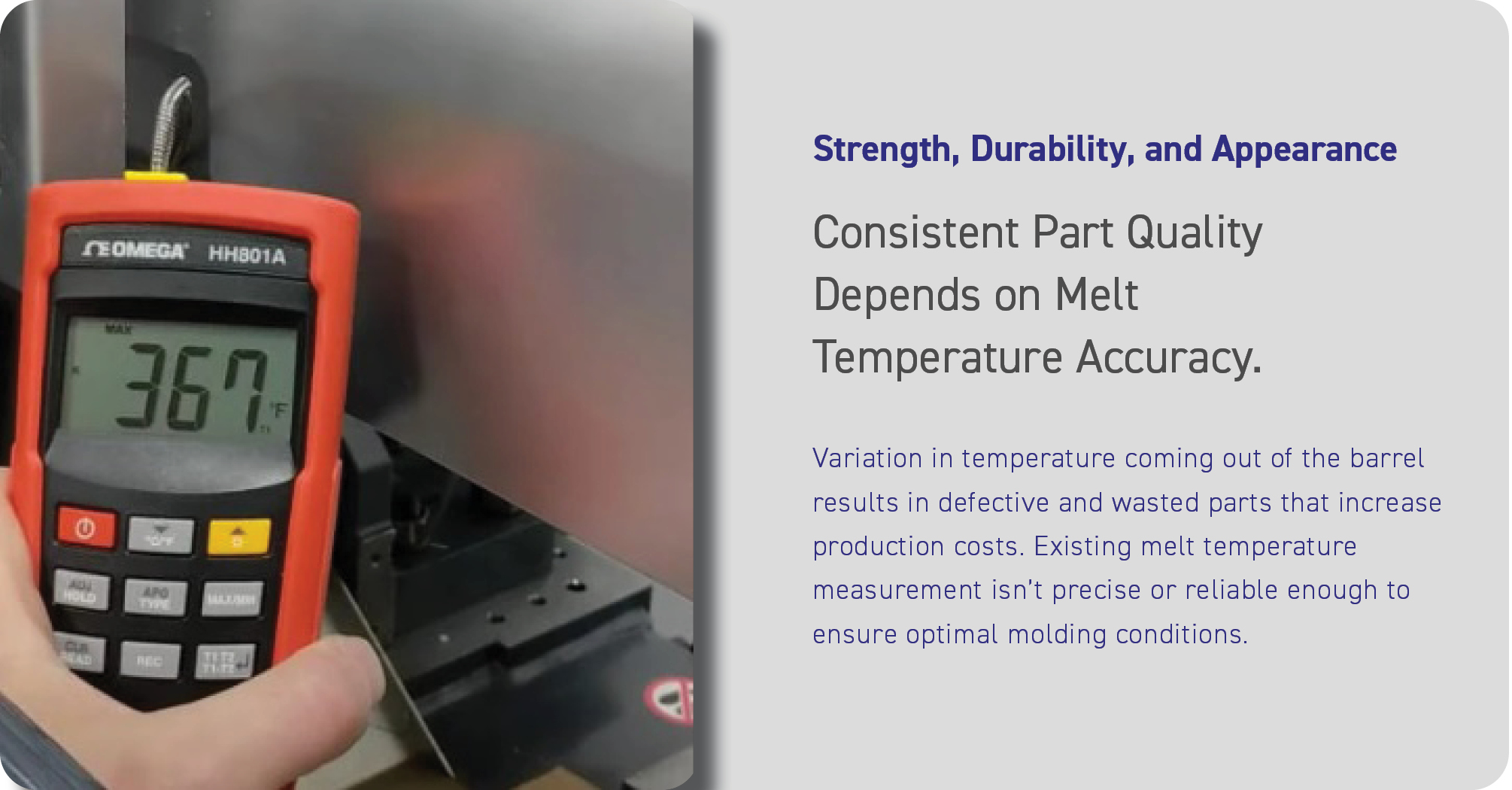

Do you know the melt temperature of your plastic?

FINALLY……a FAST, ACCURATE, EASY AND SAFE way to measure plastic melt temperature from press-to-press, operator-to-operator, without human error!

FEATURES & BENEFITS

- Low-Cost Purge: MTMS $1.75 per purge vs. probe-immersion purge at $10+ per purge on average

- Safety: No hands are in or near the purge during measurement

- Eliminates Human Error: No manual probe-immersion purge

- Increases Production & Decreases Downtime: Measures temperature in under 1 minute, and as low as 35 seconds

- Measures shot sizes down to 1 ounce

- Repeatable from operator-to-operator, press-to-press

- Accurate within +/-1%

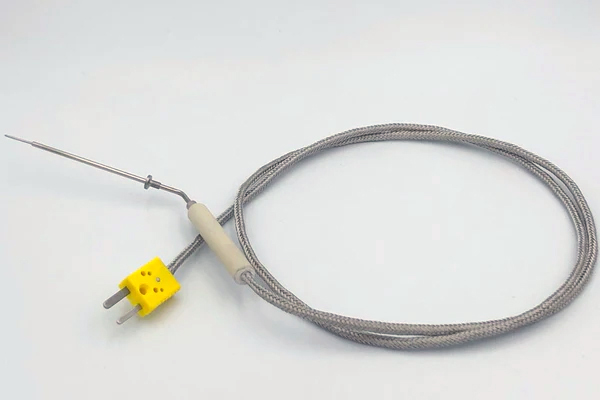

- Heavy duty, long lasting thermocouple probe designed for rapid heat transfer

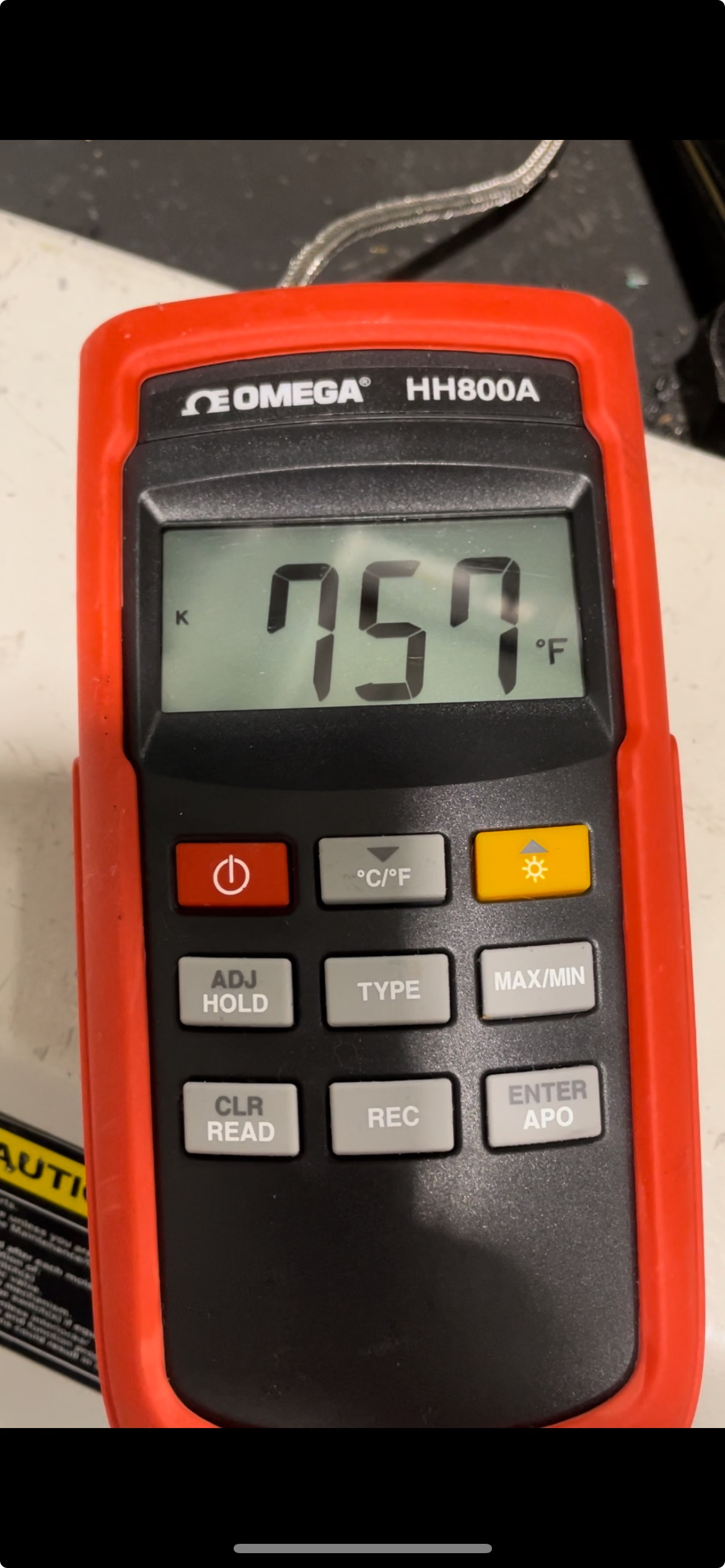

- Fast-reading pyrometer 3x per second

- Patented insulated purge cups designed for precise probe positioning keeps the heat/BTUs in the cup and prevents skinning

- Heavy duty purge cup ring made from H-13, 52-54Rc hardened steel holds purge cup in place and provides precise flow path for thermocouple probe tip

- Sturdy purge puck with magnets

- Kit Includes: (1) Fast-reading Pyrometer, (2) Proprietary Thermocouple Probes, (1) Purge Puck with Magnets, (1) Hardened Steel Ring (H-13, 52-54Rc), (50) Insulated Purge Cups (one-time use)

How the MTMS Kit Works:

MTMS is based on two major principles:

- Keeping the purge molten by using and insulated purge cup

- Normally, in the injection molding industry, we focus on solidifying the resin rapidly by cooling the resin quickly so we can produce more parts per hour. However, the MTMS focuses on keeping the purge material molten so the thermocouple can detect the temperature before the material “freezes” or “skins”. When the material skins the tip is now insulated and this prevents the thermocouple from measuring the melt temperature accurately.

- Precisely position the thermocouple probe in the effective flow path of the material or purge

- This also includes a wiping action over the thermocouple probe to eliminate skinning. The precise positioning of the thermocouple also eliminates human error and provides a more repeatable and accurate melt temperature.

NOTE: A minimum of 1 ounce purge is required for accurate melt temperature measurement.

Why Measure Plastic Melt Temperature?

- Melt Temperature

- Flow

- Pressure

- Cooling

Products:

| ITEM NO | PRODUCT | DESCRIPTION |

| 10100 | MTMS Kit | (1) Fast-reading Pyrometer, (2) Proprietary Thermocouple Probes, (1) Purge Puck with Magnets, (1) Hardened Steel Ring (H-13, 52-54Rc), (50) Insulated Purge Cups (one-time use) |

| 10200 | Purge Puck with (2) Magnets | Aluminum puck that precisely positions the assembly in the locating ring on the injection molding press |

| 10300 | Hardened Steel Ring | H-13, 52-54Rc Hardened Steel ring that holds the purge cup in place and provides hardened radiused seat for nozzle |

| 10400 | Pyrometer | Fast-reading pyrometer with peak temperature hold & rapid scan rate |

| 10500 | (2) Thermocouple Probes | Heavy duty thermocouple probes proprietary to the MTMS Kit, engineered for rapid rate heat transfer, includes built-in stopper |

| 10700 | (2) Magnets | Replacement magnets for purge puck |

| 20250 | (250) Purge Cups | One-time use insulated purge cups, quantity of 250 |

| 20500 | (500) Purge Cups | One-time use insulated purge cups, quantity of 500 |

| 21000 | (1000) Purge Cups | One-time use insulated purge cups, quantity of 1000 |