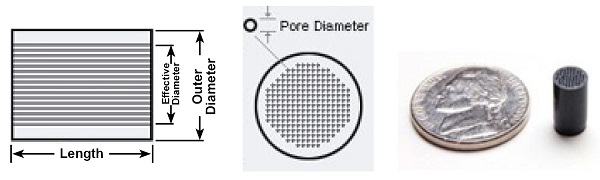

Composed of several straight and uniform pores allowing air or gas that gets trapped inside the mold cavity during injection, or die casting process to escape freely. Vents act like release windows, while keeping in the molten material. To optimize mold design and reduce the possibility of manufacturing defective parts, specify strategically placed insertion points to hold the vents.

FEATURES & BENEFITS

- Fast and easy exchange of venting plugs; easy cleaning of molding dies

- Peforation volumes are 5-30 times higher than ordinary venting plugs

- Decrease replacement frequency of venting plugs

- Drastically decreases defects such as pin holes, mis-run, and short-shots

- Pore sizes range from 0.03 to 0.5 mm; length and diameter of vents to meet your needs

Vents with a pore diameter of 0.3 to 0.5 mm are ideal for low pressure and gravity die casting parts. Vents with ultra fine pores (0.03 mm to 0.1 mm) are typically specified for plastic injection mold applications.

- We can supply vents made to your specification as well as standard sizes.

- Actual pore diameters may vary slightly from specifications

- During installation, do not strike the vent pores

- Keep insertion tolerances between 0.025 and 0.05 mm